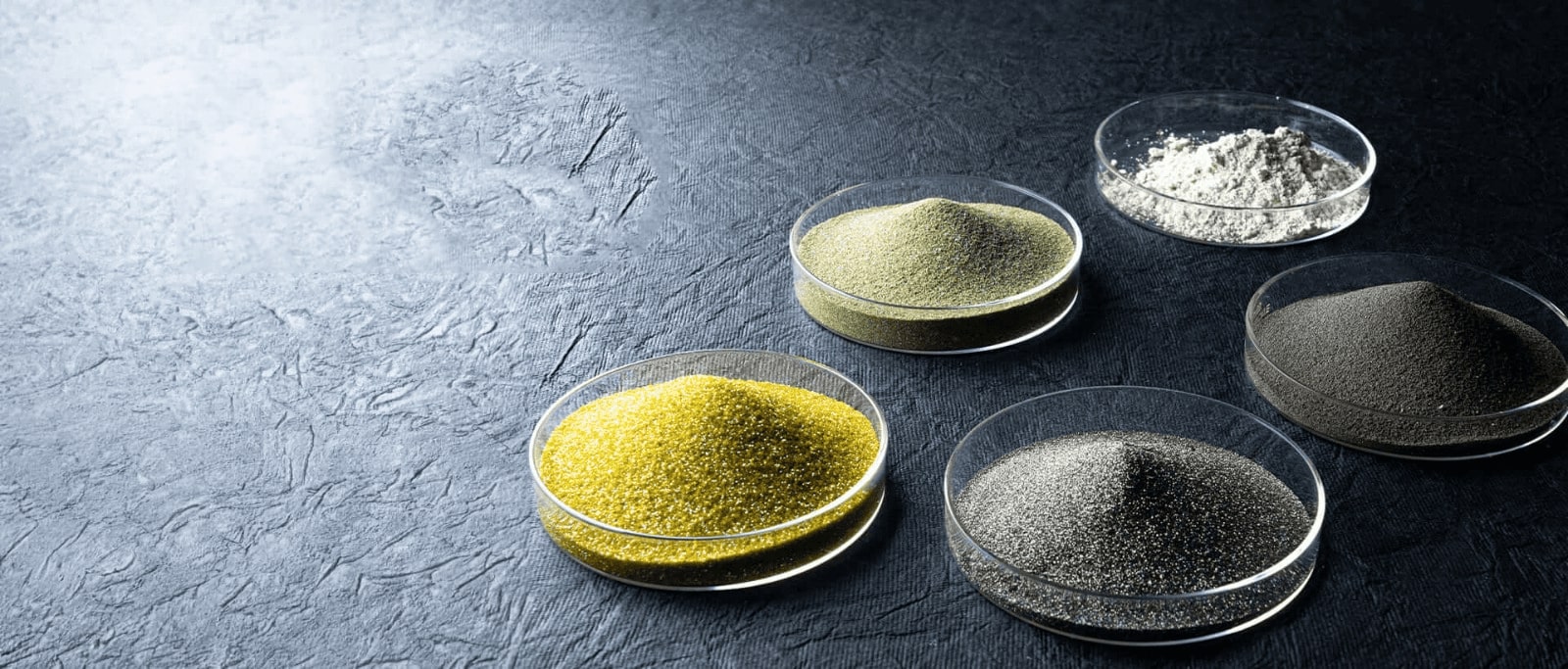

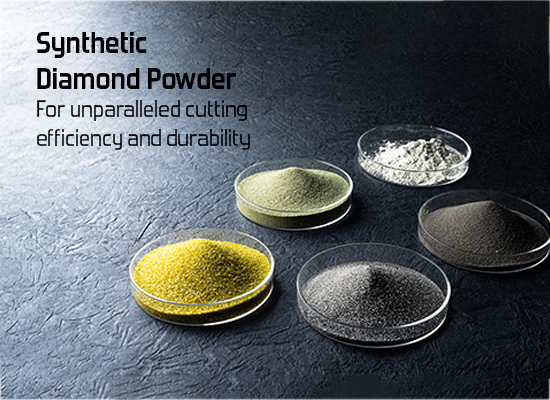

Our high-performance synthetic diamond powder are made with the industry's leading technology. These micron-sized particles deliver unparalleled cutting efficiency and long-lasting durability.

Applications for Diamond Powders.

Jewelry and Gemstone Industry

Ideal for polishing and lapping gemstones like sapphire, diamonds, and others, achieving exceptional luster and precision finishes.

Optics and Glass Manufacturing

Perfect for polishing and shaping high-quality lenses, prisms, and other optical components, ensuring clarity and surface perfection.

Electronics and Semiconductors

Enable high-precision grinding and lapping of delicate electronic components, promoting smooth surfaces and optimal device performance.

Automotive Industry

Facilitate superior polishing of engine components, pistons, and other parts for reduced friction, wear, and improved efficiency.

General Machining and Manufacturing

Applicable for grinding and polishing tools for a wide range of hard materials like ceramics, composites, and even other superhard materials.

Beyond the Ordinary

Nickel and Titanium Coated Diamond Powders.

In addition to our core offering, we also provide innovative nickel and titanium coated diamond powders.

Nickel-coated diamond powders excel in

Thermal Management Applications

Heat sinks and other thermal management components benefit from the enhanced thermal conductivity, promoting cooler grinding and reducing heat-induced damage.

Extended Tool Life

Improved metal bond strength translates to longer-lasting performance in metal bond grinding tools.

Titanium-coated diamond powders provide

Smoother Cutting

Increased lubricity allows for smoother cutting action and reduced friction during the grinding process. Superior chemical resistance makes them ideal for grinding and cutting where there is heat generated when using regular diamond powders.

Andheri (West), Mumbai - 400 053, India

T: +91-22-40649100

Mon-Fri: 9am to 6pm

Schedule a consultation with our team today.