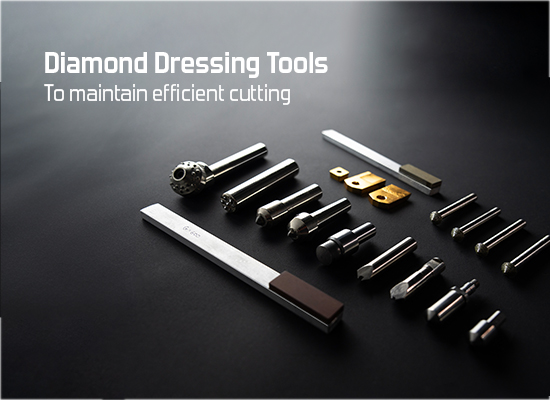

Diamond dressing tools are essential for maintaining the cutting efficiency of grinding wheels. They function by truing and dressing the grinding wheel, which involves

Truing

Correcting any unevenness or runout on the grinding wheel's surface.

Dressing

Exposing fresh, sharp abrasive grits on the grinding wheel for optimal cutting performance.

There are two main types of diamond dressing tools: single point and multi point. Here's a breakdown of their characteristics to help you choose the right one for your needs

Single Point Diamond Dresser

Features

- A single diamond cutting point mounted on a shank.

- Offers precise control and maneuverability.

- Ideal for intricate dressing profiles and small grinding wheels.

Applications

- Creating specific shapes and profiles on the grinding wheel.

- Dressing small-diameter wheels or limited surface areas.

- Achieving high-precision finishes.

Multi Point Diamond Dresser

Features

- Contains multiple diamond cutting points arranged in a linear or wheel shape.

- Provides faster dressing due to its broader contact area with the grinding wheel.

- Well-suited for larger grinding wheels and flat surface dressing.

Applications

- Dressing large grinding wheels for improved efficiency.

- Rapidly removing material buildup on the grinding wheel.

- Achieving consistent finishes on flat surfaces.

Choosing Between Single Point and Multi Point

- Consider the size of your grinding wheel: Single point for small wheels, multi point for larger ones.

- Desired dressing profile: Single point for intricate shapes, multi point for flat surfaces.

- Speed requirements: Multi point offers faster dressing for larger jobs.

- COST: Single point dressers are generally less expensive.

Additional Factors

- Diamond grit size: Choose the appropriate grit size depending on the material you're grinding and the desired level of aggressiveness.

Andheri (West), Mumbai - 400 053, India

T: +91-22-40649100

Mon-Fri: 9am to 6pm

Schedule a consultation with our team today.