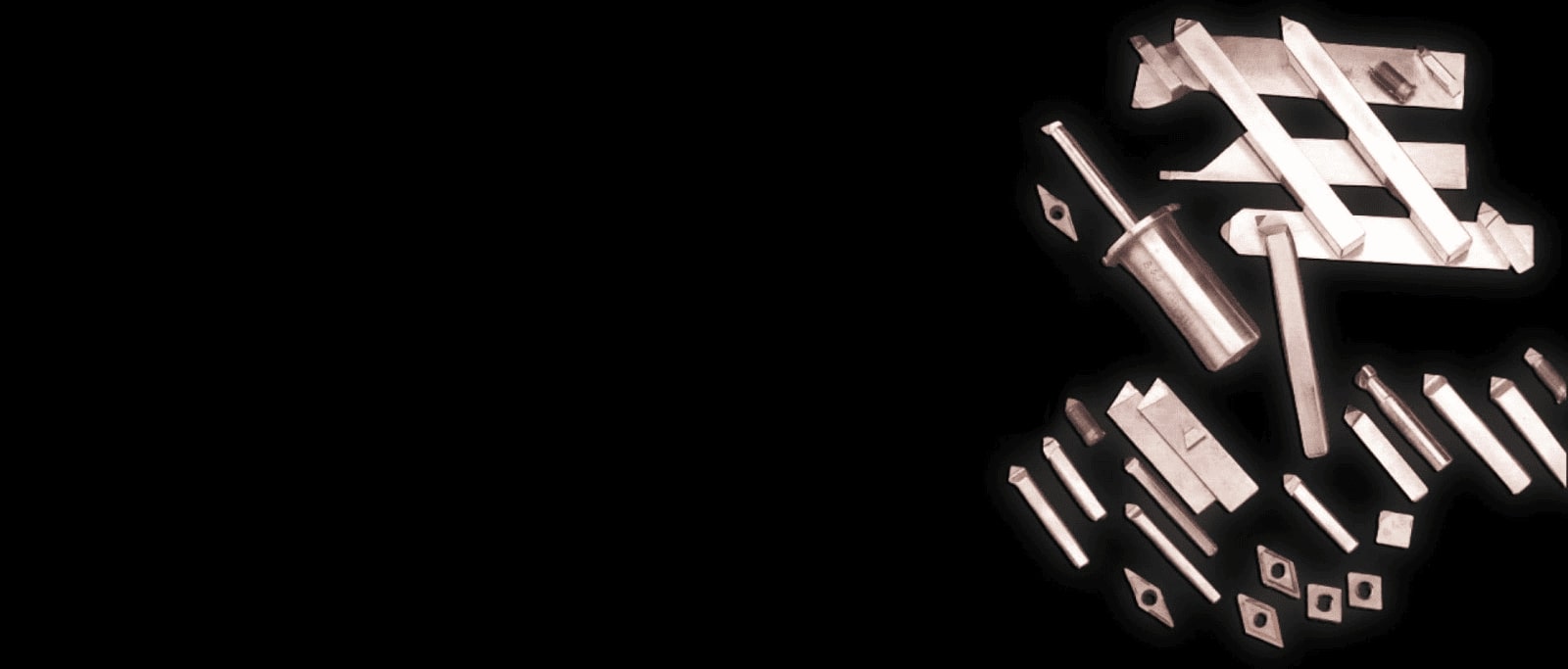

-tools.jpg)

POLEX Polycrystalline Diamond Tools are designed for superior performance and extended tool life in various industrial applications. Here's a closer look at what makes them a valuable choice.

Polycrystalline Diamond (PCD) Technology

Unlike traditional diamond tools with mono diamond crystals, POLEX utilizes PCD, a layer of microscopic diamond particles sintered together.

This innovative technology offers exceptional hardness and wear resistance, resulting in:

- Faster cutting speeds: PCD's superior cutting ability allows for increased productivity.

- Longer tool life: The extreme durability of PCD translates to fewer tool changes and reduced downtime.

- Consistent finishes: PCD maintains its cutting edge for extended periods, ensuring consistent results throughout the project.

Benefits of Choosing POLEX Polycrystalline Diamond Tools

Improved Overall Efficiency

Faster cutting speeds, longer tool life, and reduced downtime contribute to significant gains in productivity.

Enhanced Precision and Control

PCD's ability to maintain a sharp edge allows for precise cuts and consistent results.

Cost-Effectiveness

While the initial investment might be higher than traditional tools, POLEX PCD tools offer significant cost savings in the long run due to their exceptional durability.

Applications of POLEX Polycrystalline Diamond Tools

POLEX PCD tools are versatile and can be used in a wide range of industries, including:

- Woodworking: Ideal for cutting and shaping hardwoods, softwoods, and composite materials.

- Electronics: Precise machining of circuit boards, heat sinks, and other electronic components.

- Construction: Cutting and drilling through concrete, asphalt, and other abrasive materials.

- Automotive: Machining engine components, transmissions, and other automotive parts.

- Aerospace: Manufacturing lightweight and high-strength components for the aerospace industry.

Finding the Right POLEX Polycrystalline Diamond Tool

POLEX likely offers a wide variety of PCD tools to suit specific applications. Here are some factors to consider when choosing the right tool:

- Material you're working with: Different materials require specific PCD tool geometries and diamond grit sizes.

- Application requirements: Consider the desired cutting depth, finish quality, and tool size needed for your project

- Compatibility with your machine: : Ensure the chosen PCD tool shank or mounting system is compatible with your equipment.

Andheri (West), Mumbai - 400 053, India

T: +91-22-40649100

Mon-Fri: 9am to 6pm

Schedule a consultation with our team today.